- Network system construction: Including access networks, wireless WiFi coverage, and industrial computer LAN - Surveillance installation: Perimeter security, warehouse video monitoring, production equipment monitoring - Server setup: Operation maintenance servers and industrial computers - Data center construction: Main server racks, UPS power supply, PDU power distribution, etc.

MoreYEARS OF SHELF PRODUCTION EXPERIENCE

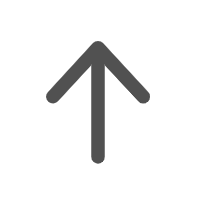

Extensive Project Experience

- Efficient execution: With rich experience, our team masters all construction processes, allocates resources precisely, and handles emergencies promptly to ensure on-time or early delivery.

- Technical expertise: Years of R&D have equipped our team with solid knowledge and excellent skills. We stay updated with cutting-edge technologies to deliver industry-leading quality.

- Quality control: Our strict standards cover material selection, construction supervision, and comprehensive pre-delivery inspections to guarantee premium quality.

- After-sales commitment: Our professional support team provides rapid response and effective solutions to eliminate your concerns.

Comprehensive Service Process

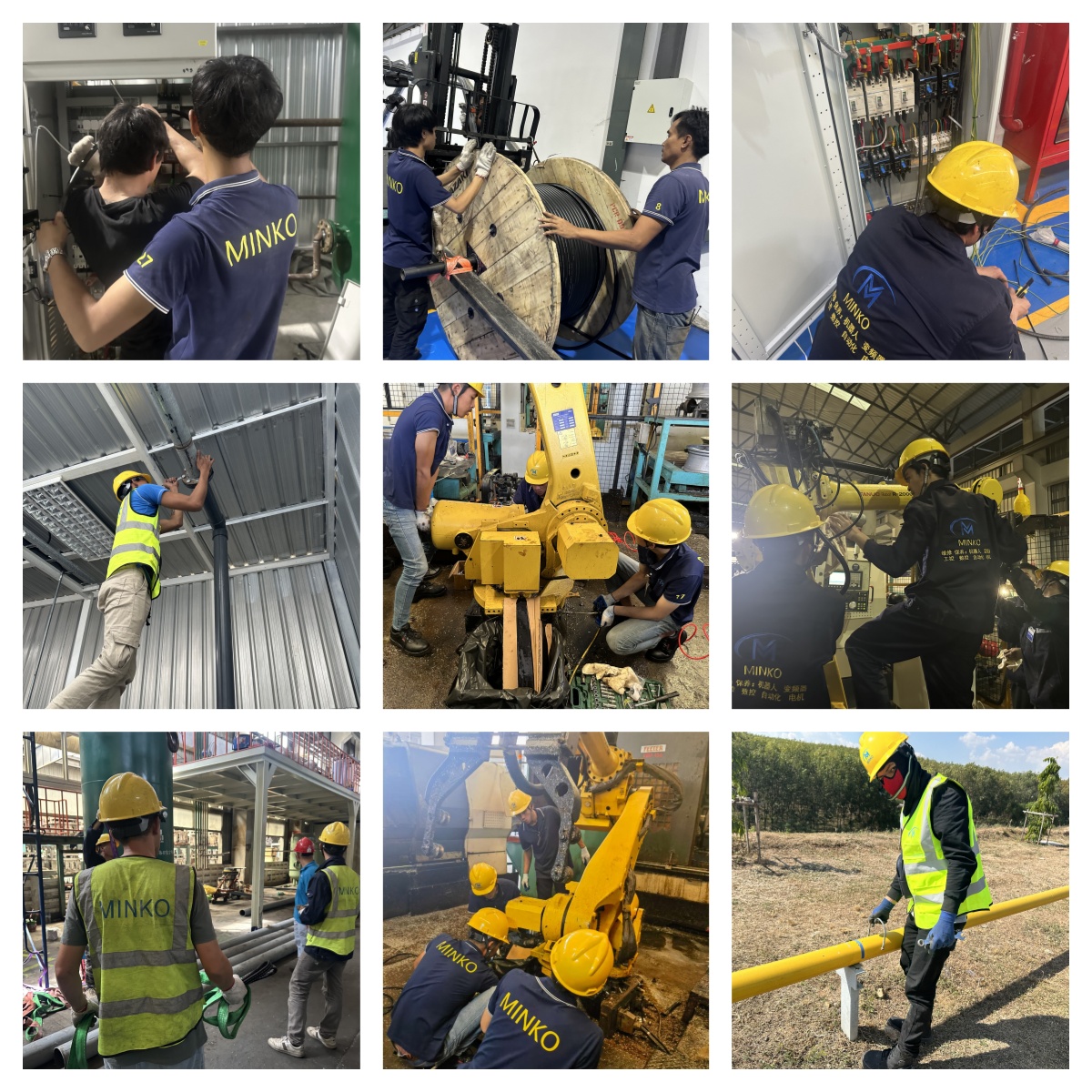

- Advanced digital maintenance equipment (precision circuit testers, intelligent diagnostic systems) for accurate fault detection.

- Certified maintenance engineers with extensive expertise and practical experience.

- Regular technical training to ensure up-to-date service capabilities.

- Professional quality diagnosis, repair, testing, and equipment cleaning:

* Full inspections using specialized tools/methods

* Standardized repair procedures with premium parts

* Thorough post-repair testing under simulated conditions

* Deep cleaning to enhance appearance and longevity

Quality control: Our strict standards cover material selection, construction supervision, and comprehensive pre-delivery inspections to guarantee premium quality.

After-sales commitment: Our professional support team provides rapid response and effective solutions to eliminate your concerns.

Years of project construction experience is our confidence and a strong guarantee for providing you with quality service.

FACTORY DIRECT SALES, REDUCING PURCHASE COSTS

Advanced digital maintenance equipment (precision circuit testers, intelligent diagnostic systems) for accurate fault detection.

Certified maintenance engineers with extensive expertise and practical experience.

Team members regularly participate in technical seminars and training courses to stay updated on the latest repair technologies and industry trends, ensuring they can provide customers with cutting-edge repair services.

Professional quality diagnosis, maintenance, testing, and equipment cleaning: In the quality diagnosis stage, specialized detection tools and methods are used for comprehensive testing of the equipment, including functionality tests, performance assessments, and stability checks, to accurately identify any existing issues. The maintenance process strictly follows standardized operating procedures, using high-quality repair parts and materials to ensure that the maintenance quality reaches industry-leading levels. After maintenance, the equipment undergoes thorough testing, simulating various actual usage scenarios to ensure that it returns to normal operation with stable and reliable performance. Finally, the equipment is deeply cleaned, including the outer shell and internal components, removing dust, stains, etc., to extend the equipment's lifespan and enhance its overall appearance and texture.

PERFECT AFTER-SALES SERVICE SYSTEM

We have a team with outstanding professional strength. This team always adheres to the principle of 'technical expertise, timely service, and reasonable prices', wholeheartedly creating an unparalleled quality experience for our clients.

At the technical level, the team members are all elites in the industry, possessing profound expertise and rich practical experience.

When it comes to services, we are well aware of the importance of timely response. We have established an efficient service system that can respond quickly as soon as customers make a request.

Regarding pricing, we firmly believe that reasonable prices are the cornerstone of establishing long-term cooperative relationships with our clients. By optimizing internal management processes and reducing operational costs, we provide customers with highly cost-effective solutions while ensuring service quality. It is precisely due to the strength of our professional team that we have earned a good reputation and the trust of numerous clients in the market. In the future, we will continue to uphold our mission, continuously enhance team capabilities, and provide better technical services for our clients, working together to create a bright future.

Contact Us

Sitemap

Swipe to follow us

Qingdao Ice凌 Automation Technology Co., Ltd. All rights reserved.